Why Multi-Venturi Outperforms Traditional Injectors

Share

Why Grow Greenie's Multi-Venturi Injectors Are the Future of Gas Injection and Fluid Mixing

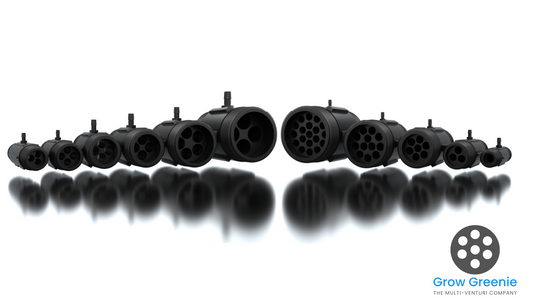

When it comes to gas injection and fluid mixing, the choice of injector technology can make a big difference in performance, efficiency, and maintenance. For decades, the standard single venturi injector has been a widely used solution across multiple industries like aquaculture, wastewater treatment, and more. However, as demands grow for higher performance, quieter operation, and more energy-efficient systems, Grow Greenie’s patented multi-venturi injectors are proving to be a powerful next-generation alternative.

In this article, we’ll explore the key differences between Grow Greenie Multi-Venturi Injectors and traditional venturis, like the Mazzei injectors, and why multi-venturi technology may soon replace these conventional single-venturi designs.

1. Design Innovation: Single vs. Multi-Venturi

Standard injectors, like Mazzei injectors for example, are based on a single-venturi principle, where one nozzle creates a vacuum by narrowing flow and drawing in air or gas. While effective, this method is limited by its geometry and produces higher back pressure on pumps and lower suction rates.

Grow Greenie’s MacroMixer injectors use multiple precision-engineered venturis working in parallel. This patented multi-venturi configuration distributes flow evenly, significantly reducing back pressure while enhancing suction power, mixing efficiency, and outflow pressure. This design not only reduces strain on pumps but also allows greater flexibility in system integration.

2. Superior Mixing and Oxygen Transfer Efficiency

Whether you're injecting oxygen, ozone, CO2, or nutrients, efficient gas transfer is key. Grow Greenie’s MicroBubbler injectors produce millions of microbubbles, increasing the gas-liquid contact surface area and accelerating gas dissolution.

3. Reduced Noise and Vibration

Traditional single venturi injectors are known for producing high-pitched slurping noise. This is due to intense velocity changes inside a single narrow passage that is vacuuming in back pressured water as well. This can be disruptive in sensitive environments like laboratories, aquariums, or RAS facilities.

Grow Greenie’s multi-venturi design creates a quieter, more stable flow, distributing cavitation across several points instead of concentrating it in one area. The result is smoother operation and a more user-friendly experience.

4. Energy Efficiency & Cost Savings

Because Grow Greenie injectors suction in more gas and liquid, they enable users to downsize pumps and reduce system energy loads. This translates to real operational savings and improved ROI.

With no need for bulky air compressors or diffusers, Grow Greenie systems simplify aeration and mixing with fewer components and lower installation costs.

5. Made in the USA & Backed by Patents

Grow Greenie is proudly family-owned and operated in Sarasota, Florida. Our injectors are made from high-quality materials sourced in the U.S., and our technology is protected by multiple U.S. patents, including:

- Patent No. 11,701,625: MicroBubbler Technology

- Patent No. 12,010,958: MacroMixer Multi-Venturi System

These patents represent a new standard in fluid mixing and aeration.

The Future of Fluid Mixing is Multi-Venturi

The Grow Greenie Multi-Venturi system offers a smarter, more efficient, and more reliable solution than traditional single-venturi injectors. With lower energy needs, quieter operation, reduced maintenance, and unmatched microbubble performance, it’s the next step forward in water oxygenation and gas injection technology.

Whether you're managing an aquaculture operation, treating wastewater, or running a hydroponic farm, upgrading to Grow Greenie multi-venturi injectors can help you achieve better results with less hassle.

Explore our full line of injectors at www.growgreenie.com and experience the difference for yourself.

Comparison Chart of the Multi-Venturi vs. A Traditional Venturi

|

Feature |

Grow Greenie (Multi-Venturi) |

Traditional Venturi Injectors |

|

Design |

Multi-venturi configuration with parallel mixing zones |

Single venturi design with one injection throat |

|

Back Pressure (this applies to the MacroMixer Injector Only) |

Minimal back pressure; maintains strong outflow |

High back pressure; restricts flow post-injection |

|

Efficiency |

Greater suction with less energy input |

Requires more pump power to overcome resistance |

|

Gas-Liquid Transfer |

High-efficiency mixing with multiple diverging venturis |

Standard gas dispersion; limited bubble refinement |

|

Noise Level |

Ultra-quiet operation |

Often noisy, especially under high pressure |

|

Installation |

Compact, plug-and-play setup; adaptable to small or large systems |

Often designed much longer and hard to fit in compact spaces |

|

Applications |

Aquariums, hydroponics, ponds, wastewater, agriculture, aquaculture |

Primarily industrial, municipal, or irrigation use |

|

Scalability |

Works across small and large systems without major redesigns |

Less efficient at small scale; scaling needs engineering |

|

Noise Suppression |

Built-in quieting due to design geometry |

Noise dampening requires external solutions |

|

Material Quality |

Premium domestic materials, made in the USA |

Varies widely by brand and use case |

|

Innovation Status |

Backed by two U.S. utility patents for multi-venturi tech |

Based on legacy designs with incremental changes |